Lists, Tips and Tricks

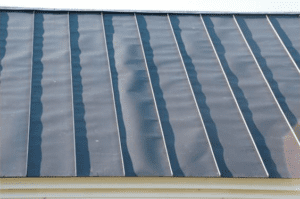

5 Ways to Minimize Oil Canning on Metal Roofs

What is Oil Canning?

Oil canning is defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. In other words, it’s a visual phenomenon that makes metal panels look wavy or somewhat distorted, especially in the broad, flat areas of a metal roof or wall system. Oil canning can occur with any type of metal materials used in construction

Luckily, there are specific methods and practices that will help minimise the chance of oil canning development. Before we begin, please keep in mind that doing one or more of these recommendations does not mean you won’t have oil canning; sometimes it’s just an inherent and unavoidable variable with metal.

#1: Use ribs to break up the flat space on a panel

Rib rollers (also called stiffening ribs or striations) are the manufactured indentations or “patterns” roll formed into the flat portion of metal panels between the seams. While these indentations don’t prevent oil canning from happening, it does break up the amount of flat surface and makes oil canning less apparent and less likely to happen. Common ribs include:

- Ribbed

- V-Ribs

- Bead

- Pencil

- Striated

- Corrugated

- Clip relief

- BoxProfile

#2: Install the metal panels on a level, consistent, and in-plane roof deck

An uneven roof deck, whether it’s made of metal, plywood, or oriented strand board (OSB), is one of the most common reasons oil canning occurs. If the metal panels are installed on top of Counter-battens that bow or are inconsistent in its plane, stresses are inflicted on the metal as it tries to conform to this uneven surface. Always use the proper methods to ensure the roof deck is level before any panels or accessories/ components are installed.

More details about a correct subroof set up HERE

#3: Use a low-gloss or matte finish to reduce reflectivity

Because the amount of light reflecting off of a metal roof or wall system makes such a difference in regards to the visibility of oil canning, using a coil or sheet with a low-gloss or matte finish is the best way to ensure reflectivity is reduced.

#4: Install panels with narrow widths

Since oil canning tends to be most visible in the broad, flat areas (see point 1) of a metal roof or wall system, reducing the amount of those flat areas by choosing smaller and narrower panel widths (18” or less) is a common practice.

#5: Use backer rod or other similar shimming materials

he addition of backer rods or shimming materials under the clips to help flatten out an uneven roof plane can help relieve oil canning in some cases. According to the MCA:

“Some designers specify the use of ‘backer rod’ or other similar types of shimming materials on the panel underside when installation is over a solid substrate. Backer rod is a compressible foam strip normally used in the concrete and masonry trades in joints to serve as a backing for a caulk joint. For certain types of metal panel systems it causes the center of the panel to ‘pillow’ uniformly, relieving stress and reducing the visual effects of oil canning.”